|

|

(click to enlarge)

SPS, Inc., a licensed general contractor (California State License No. B1-309472), is staffed with an experienced team of skilled professionals who undertake all aspects of structural concrete rehabilitation, restoration, repair and reinforcement for a variety of commercial and industrial buildings, parking structures and slabs.

As active members of the American Concrete Institute, ACI, and the International Association of Concrete Repair Specialists (IACRS), the SPS team brings both current technology and a 20 year reputation for prompt, effective, cost-conscious performance to structural concrete repair tasks.

SPS' comprehensive knowledge of the repair and restoration process begins with expert diagnostics. Experienced visual inspection, as well as highly reliable analytical testing, identifies causes of cracks and failures, and aids in determining the fullest possible range of repair alternatives. For instance, SPS crack injection repair is most effective in restoring concrete monolithically with adhesive bonds as strong as concrete. However, crack injection alone may at times be insufficient to solve the whole problem, especially in overstress conditions.

Our success is a result of creating and implementing a range of innovative alternatives, giving clients full advantage of proven advancements in techniques, equipment and engineering.

SPS Crack Injection Restoration

By incorporating expert

diagnostic techniques and evaluation with design,

construction, materials and engineering specialties, SPS

crack injection insures that its use is both an appropriate

and highly effective method of concrete repair and

restoration.

(click to enlarge)

The Right Solution Begins With Identifying The Problem

SPS team solutions begin with an analysis of the cause of concrete problems. Armed with this knowledge, whether structural weakness, static capacity, SPS works with engineers and clients to relieve the cause of the problem and put in place a range of repairs, as needed. Common causes of cracking include:

- Shrinkage cracking during cure

- Mechanical overload, either static or dynamic

- Temperature changes unprovided for in original design

- Base or foundation settlement

- Faulty structural design, improper placement of structural steel, inadequate concrete load strength, insufficient vibration and compaction or other human error.

Identifying The Best Repair Procedure

SPS will work in conjunction with its own consulting structural engineers, or in concert with client/contracted engineers to determine the appropriate repair and restoration methods and alternatives.

As a contractor specializing in concrete repairs, we are experienced in the following repair procedures:

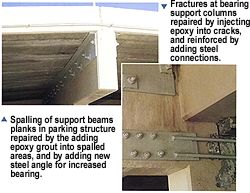

- Epoxy Injection -High strength epoxy is injected into cracks in concrete to "weld" back concrete to monolithic properties.

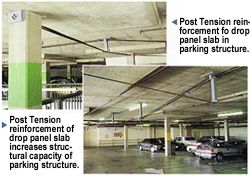

- Post Tensioning- Steel cables or rods are added to exterior of concrete beams or the underside of pre-stressed slabs to increase the structural capacity of these members.

- Adding Structural Reinforcement Steel- Where the existing embedded reinforcing steel is structurally insufficient or damaged, additional strength maybe obtained by installing steel plates, channels, angles, etc. to the exterior surfaces of concrete elements.

- Flexible Sealing and Waterproofing-An elastic material is used to seal and waterproof "cold joints " in concrete where movement is expected.

- Surface Treatments &

Overlays - Protection of concrete surfaces to resist

water and/or chemical damage.

Glu-Laminated Beam Repair | Concrete Repair/Post Tension | Seismic Retrofit

Home Page | SPS Clients | Contact Us

© SPS Inc. All Rights Reserved